Unlike traditional drugs, which are produced through chemical reactions, biopharmaceuticals rely on cell-based production. These living systems need specific nutrients, environments, and controls to function correctly making fermentation and cell culture critical steps in the process.

What Is Fermentation in Biopharma?

In this context, fermentation doesn’t refer to food. Instead, it’s the controlled growth of microorganisms or cell lines in large tanks called bioreactors. These cells are engineered to produce a specific protein, which will become the final drug product after purification.

During fermentation:

- Cells multiply rapidly under regulated temperature, pH, and oxygen levels

- Nutrient media feed the cells, often containing amino acids, sugars, vitamins, and trace elements

- Waste is managed to avoid toxicity

- Output is monitored to maximize yield and purity

The Role of Cell Culture

Cell culture is used especially in mammalian-cell-based production. Many biologics require cells like CHO (Chinese Hamster Ovary) cells, which closely mimic human systems and are ideal for producing complex proteins.

Cell culture systems demand:

- High-purity excipients

- Sterile conditions to avoid contamination

- Nutrient-rich media with consistent quality

- Buffer systems to maintain pH and osmolality

Key Ingredients in Biopharmaceutical Media

- Amino acids essential for protein synthesis

- Glucose and galactose primary energy sources

- Vitamins and minerals support cell metabolism

- Surfactants and stabilizers improve solubility and yield

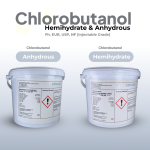

Why Grade Matters

All materials used in biopharmaceutical manufacturing must be pharma-grade or multi-compendial to meet safety and regulatory standards. Even slight variations in quality can affect the final drug’s safety, activity, and shelf life.

The Future: High-Performance, Scalable Solutions

With demand for biologics growing, manufacturers are developing ready-to-use solutions for fermentation and cell culture. These include pre-blended nutrient mixes, single-use bioreactor solutions, and GMP certified excipients, all designed to streamline production and reduce risk.

| Stage | Step | Description |

|---|---|---|

| 1. Upstream | Cell Line Development | Selection and optimization of production cell line |

| Media & Feed Optimization | Formulating ideal nutrient supply for cell growth | |

| Bioreactor Cultivation | Growing cells under controlled conditions in bioreactors | |

| Harvesting | Collecting cell culture fluid containing the target product | |

| 2. Downstream | Clarification | Removing cells and debris from the harvested fluid |

| Capture | Initial purification using chromatography or filtration | |

| Intermediate Purification | Further separation of impurities and by-products | |

| Polishing | Final purification to ensure product quality and consistency | |

| 3. Final Formulation | Formulation | Combining purified product with excipients to achieve stability and dosage |

| Sterile Filtration | Ensuring the final product is free from microbial contamination | |

| Filling & Finish | Packaging the drug product in its final container (e.g., vial, syringe) | |

| 4. Quality Control | In-Process Testing | Testing at every stage to monitor critical quality attributes |

| Release Testing | Final product is tested for safety, potency, purity before market release | |

| Stability Testing | Ensures product remains effective throughout its shelf life |