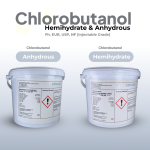

What is Pharma Grade?

Pharma Grade refers to materials active pharmaceutical ingredients (APIs) or excipients that meet stringent pharmacopoeial standards, including Indian Pharmacopeia (IP), United States Pharmacopeia (USP), European Pharmacopeia (Ph. Eur.), and British Pharmacopeia (BP). These grades are certified for direct human use in drug formulations and must be free of contaminants and impurities.

Why Does Pharma Grade Matter?

Pharma-grade materials ensure:

- Biocompatibility: Safe interaction with the human body

- Consistency: Predictable formulation performance

- Regulatory Approval: Easier product registration globally

- Patient Safety: Elimination of harmful impurities or toxins

Pharma-grade materials form the foundation of safe, effective, and compliant drug formulations. Meeting global pharmacopeial standards such as IP, USP, and EP, these excipients and raw materials ensure product consistency, patient safety, and regulatory approval, making them essential for manufacturers navigating the complex demands of modern pharmaceutical development and global distribution.

Role of Excipients in Pharma Grade Formulations

Pharmaceutical excipients are inactive components—binders, fillers, preservatives, solvents—that enable drug delivery and stability. Their grade is just as crucial as the API’s.

Common Pharma-Grade Excipients Include:

- Sodium Hydroxide IP : pH adjuster in injectables

- Sodium Hyaluronate : used in ophthalmic and dermal delivery

- Glycerol 99% Synthetic USP : solvent and humectant

- N-Acetyl-DL-Tryptophan : stabilizer in parenteral nutrition

- Mannitol IP/USP : bulking agent in tablets and injectables

Global Demand for Pharma Grade Excipients

Due to biologics, injectables, and complex drug delivery systems, pharma-grade excipients are in global demand, especially those conforming to multi-compendial standards (IP/BP/USP/EP).

Grade Verification & Certification

To verify pharma grade status:

- Certificate of Analysis (CoA) must align with pharmacopoeial standards

- Batch-wise documentation is essential

- Cross-check against regulatory databases (e.g., FDA Inactive Ingredient Database)

Understanding pharma-grade classifications is more than a regulatory checkbox—it’s a commitment to product integrityand patient safety. From excipients to APIs, ensuring compliance with IP, USP, and EP standards is essential.

Trends Shaping the Future of Pharma Grade Materials

-

- Demand for Injectable-Grade Excipients: Especially preservative-free, pyrogen-free materials.

- Green Chemistry & Synthetic Alternatives: Glycerol (synthetic) replacing animal derived options.

- Custom Grades for Biopharma: Tailored excipients for gene therapy, mRNA, and vaccines.

- AI-Driven Material Selection: Faster formulation using predictive modeling of grade compatibility.