Different formulations require different types of excipients. Based on their application, excipients are grouped into categories. Each category has a specific role in helping deliver safe and effective treatment.

A Closer Look at the Materials That Support Modern Medicines

Here is a look at some of the top categories of excipients used in modern medicine.

Amino Acid-Based Excipients

Amino acids are commonly used in injectables, biological formulations, and parenteral nutrition. These excipients act as stabilizers, buffers, or carriers. For example, L-arginine, glycine, and N-acetyl-DL-tryptophan are used to maintain pH or prevent protein degradation in sensitive drug products.

They are especially useful in products that contain proteins, peptides, or enzymes, as they help maintain the structural integrity of these molecules during storage and delivery.

Parenteral Excipients

Parenteral excipients are used in medicines given through injections, such as intravenous or intramuscular drugs. These excipients must meet high purity standards and be free of pyrogens (substances that cause fever).

Common examples include:

- Sodium chloride for tonicity

- Glycerol synthetic as a solvent or stabilizer

- Polysorbates for solubility of oily or insoluble drugs

These excipients must also be compatible with the human bloodstream and sterile to avoid adverse reactions.

Biopharmaceutical Excipients

Biopharmaceutical products are made using living cells, and they often require special excipients that support their sensitive nature. These drugs may include monoclonal antibodies, cell therapies, or gene-based treatments.

Biopharmaceutical excipients help:

- Prevent protein aggregation

- Maintain correct folding of proteins

- Ensure longer shelf life under cold storage

They often include amino acids, sugars, surfactants, and polymers specifically tailored for biologic stability.

Vaccine Formulation Excipients

Vaccines need excipients to preserve the active ingredients, boost immune response, or allow the drug to remain stable during storage and transport.

Common vaccine excipients include:

- Stabilizers like sucrose and gelatin

- Adjuvants like aluminum salts that enhance immune reaction

- Preservatives like thiomersal (in some multi-dose vials)

Because vaccines are often given to large populations, the choice of excipients must be safe, effective, and approved for use in public health programs.

Plasma Fractionation Excipients

Plasma fractionation is the process of separating blood plasma into its individual components such as albumin, immunoglobulins, and clotting factors. Excipients in these products must support sterility, stability, and purity.

Common excipients in plasma-derived products include:

- Sodium citrate as a stabilizer

- Glycine to support protein stability

- Surfactants to prevent surface denaturation

These excipients are often used in life saving treatments such as for hemophilia, immune deficiencies, and critical care support.

Multi-Compendial Solutions

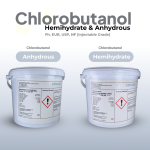

Some excipients are manufactured to meet the standards of more than one pharmacopeia, such as IP (Indian Pharmacopeia), USP (United States Pharmacopeia), and EP (European Pharmacopeia).

These are called multi-compendial excipients and are widely used in global pharmaceutical supply chains. They help simplify international regulatory approval and are often used in formulations intended for export.

These excipients undergo more rigorous testing and certification to meet overlapping requirements from multiple regulatory bodies.

Each category of excipients plays a specific role in supporting the safety, performance, and shelf life of pharmaceutical products. From injectable therapies to vaccine production, choosing the right excipient category is critical to the success of the final drug.

As drug formulations grow more complex, the demand for specialized excipients across categories like biopharmaceuticals, parenterals, and vaccines continues to rise.